1. Save PP material

Due to the tube material of pp woven bag itself has a laminating layer, and the entire bag is evenly stressed. Without the part of weak stress on sewing pinholes. Compared with the bottom sewing bag, this bag can use a thinner polypropylene base layer.

PP woven flat block valve bag can fill more full, under the same volume, it needs the area of raw material is smaller than the bottom sewing bags.

When cutting the valve bottom sewing bags, need to cut a part of raw material for valve. But for making PP woven valve sack bags, there is no situation of this waste.

2. For making Flat Block Valve bags, no need expensive adhesives(compared with sticky bottom bags) or sewing rope and sewing paper(Compared with bottom sewing bags)

3. The product quality is high, the scrap rate is extremely low, and the raw materials are saved to the greatest extent.

4. For reducing the ratio of the number of flat yarns damaged by sewing, the warp and weft density of the bottom sewing bags need to reach 50-60pcs/100mm, But the warp and weft density of Con4 bags can be reduced to 32-40pcs/100mm, which means that use AD CONVERTEX4, the output of circular looms can be increased by 50%.

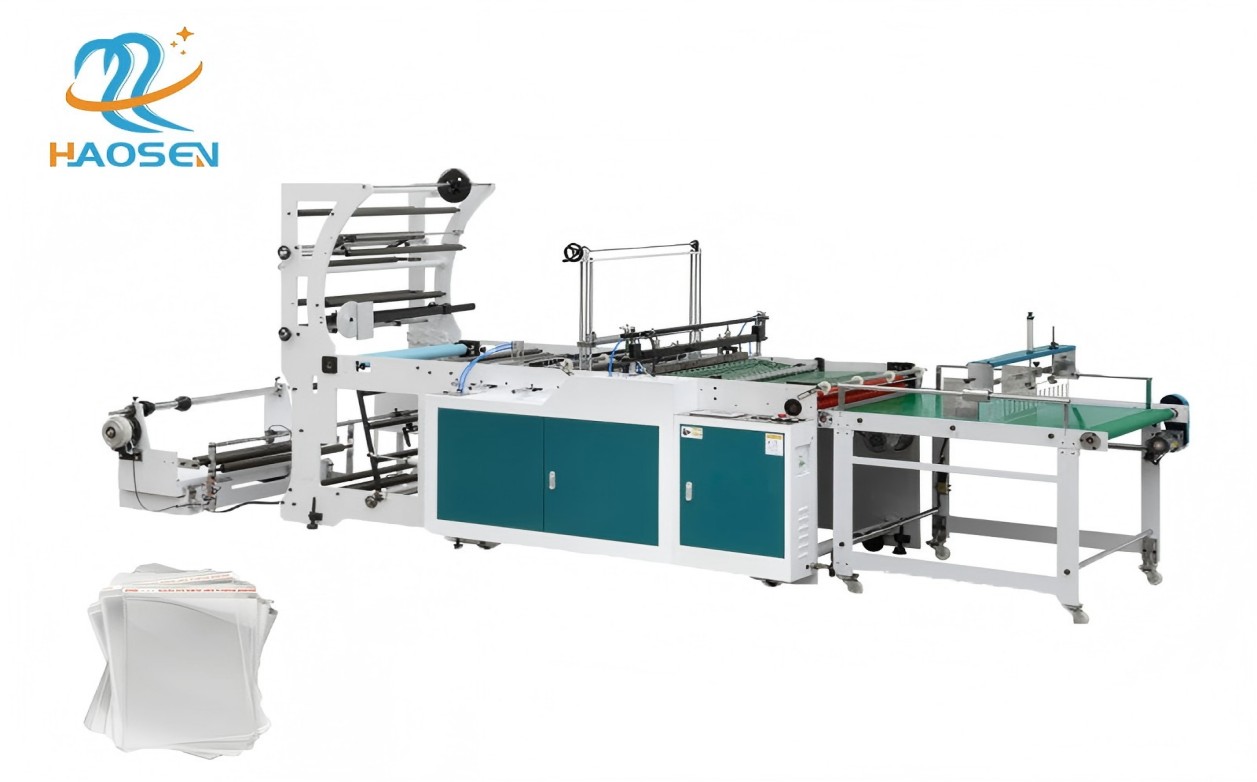

5. To operate an PP flat block valve bag making machine, only one operator and two auxiliary personnel are required per shift. Compared with the production of bottom sewing bags, it can save a lot of labor and reduce production management costs.

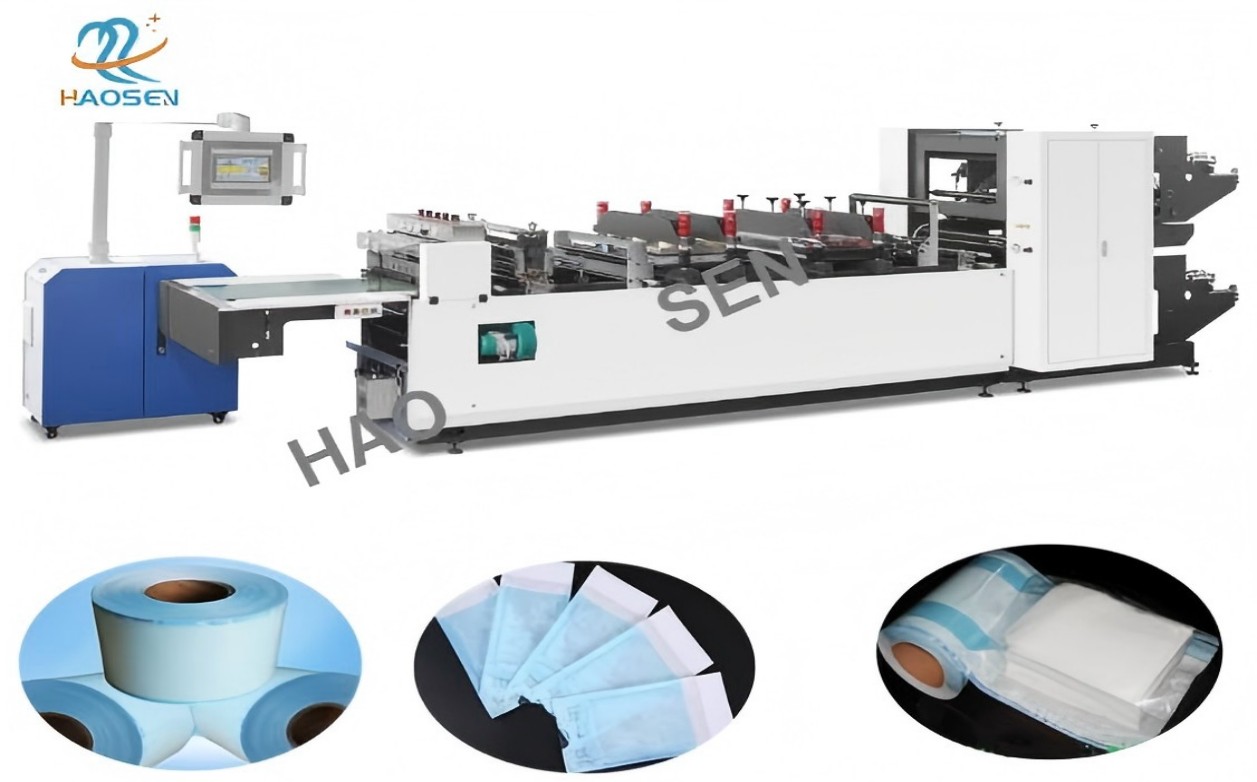

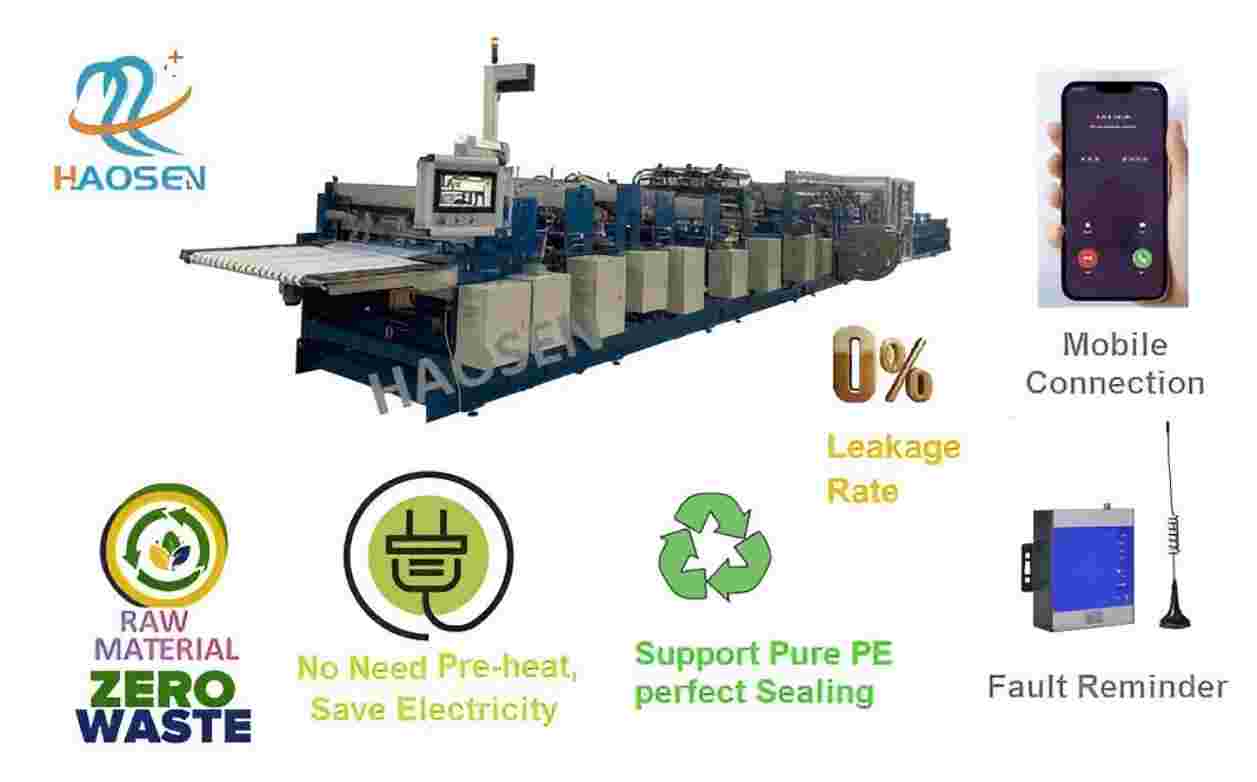

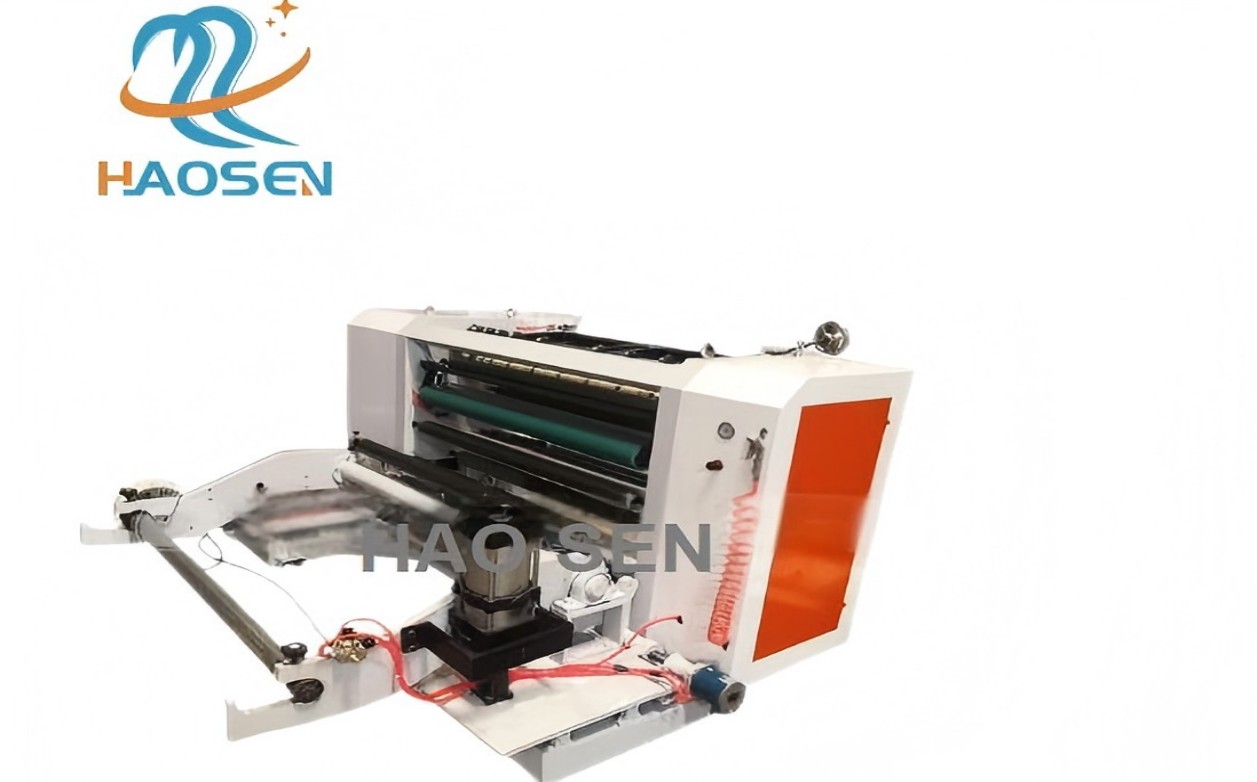

The new PP WOVEN VALVE BAG MAKING MACHINE has come out, welcome to enquire!