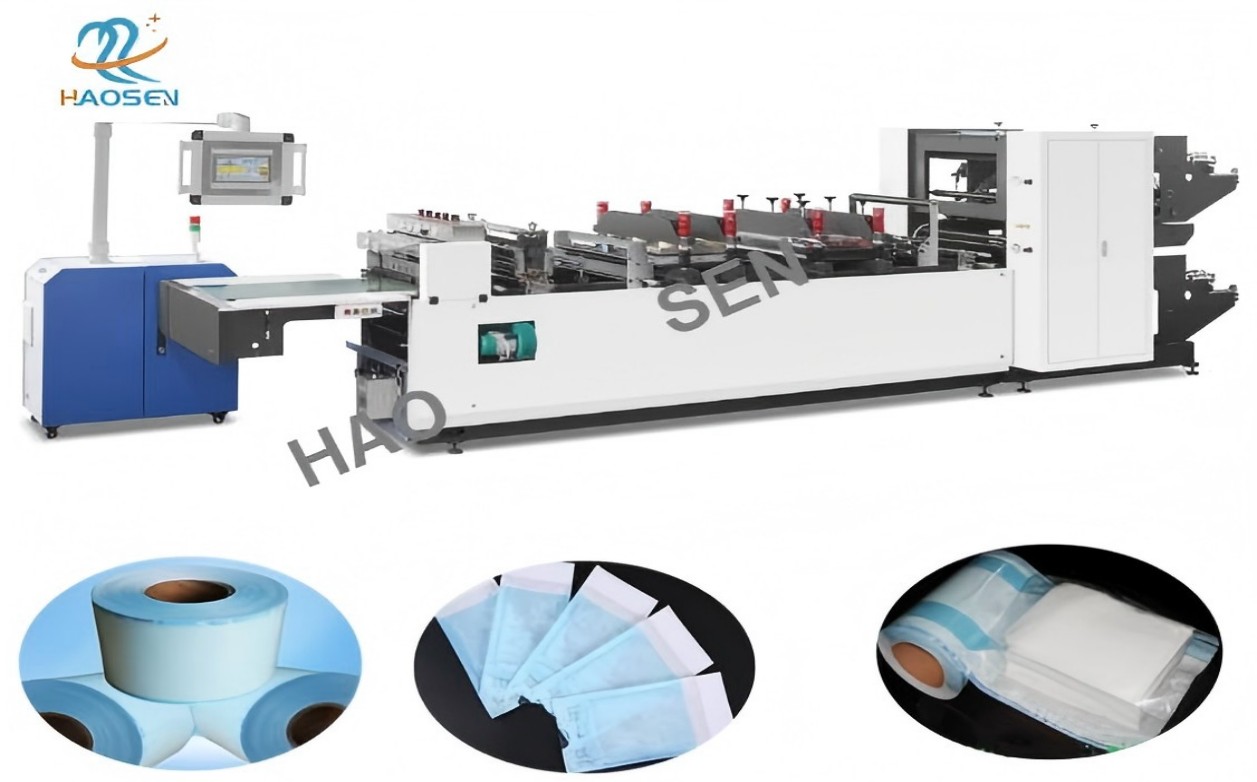

1.How to calculate the maximum width of the four-side seal?

The formula for calculating the maximum width of the four-side seal is: (film width - width of one side insertion edge - width of insertion edge * 2) / 2

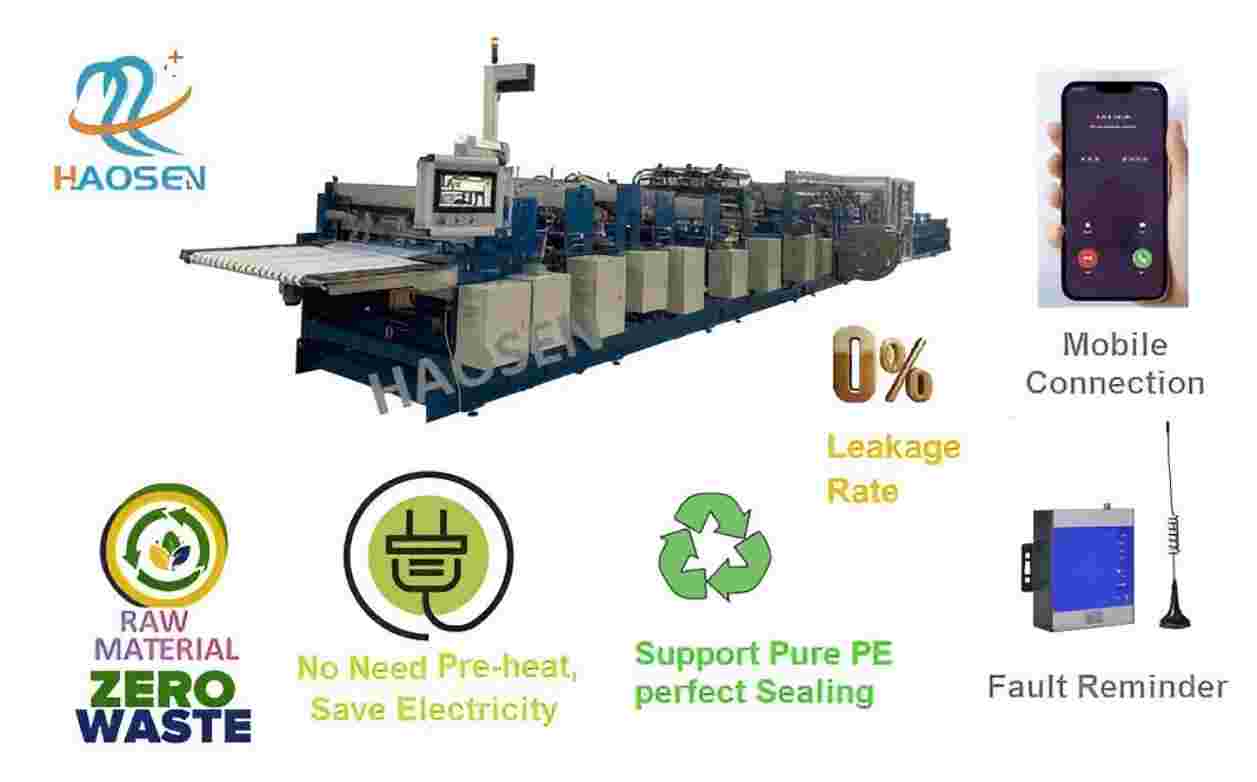

2.The application of master servo systems in machinery offers numerous significant advantages, summarized and expanded upon below:

lStable and Precise Machine Operation

High-Precision Control: Master servo motors provide precise motion control, ensuring high stability and consistency during operation. This is due to the servo system's feedback control mechanism, which allows for real-time adjustments to position, speed, and acceleration.

Fast Response Speed: Master servo motors offer a fast response speed, enabling quicker adjustments to the machine's operating state and ensuring no fluctuations or instability in precision during production.

l Quiet and Noise-Free Machine Operation

Low-Noise Design: Compared to traditional chain-driven systems, master servo motors, with their smooth power output and precise control, reduce vibration and noise during machine operation, providing a quieter working environment. This is particularly important for production lines or environments requiring quiet operation.

Reduced Mechanical Wear: Master servo systems use motor drives, rather than chains or other mechanical components, thus reducing noise generated by chain friction, gear noise, etc.

l Reduced Maintenance Costs

Eliminating Chain Maintenance Needs: Traditional machinery typically uses chain drive systems, which are prone to wear and tear after prolonged operation, requiring regular maintenance and replacement. With a main servo system, the motor directly drives the load, eliminating the need for a chain. This avoids chain wear, maintenance, and potential failures, thus reducing daily maintenance costs and downtime.

Reduced Failure Frequency: The high precision and reliability of the servo system significantly reduce the equipment's failure rate, decreasing maintenance frequency and the need for human intervention, extending the equipment's lifespan.

Reduced Component Wear: The servo system exhibits lower mechanical wear, effectively extending the lifespan of other mechanical components compared to traditional drive systems.

lSummary: By incorporating a main servo system, equipment not only achieves higher operational accuracy and stability but also reduces maintenance costs, improves the quietness of the working environment, and increases productivity, with a particularly significant advantage in reducing chain maintenance. Furthermore, the high efficiency and flexibility of servo motors allow the equipment to better adapt to changing production demands and environments. Overall, the application of servo systems significantly improves the machine's comprehensive performance and long-term economic benefits.

If you would like to learn more about a particular aspect, or if you have any other questions, please feel free to let me know!