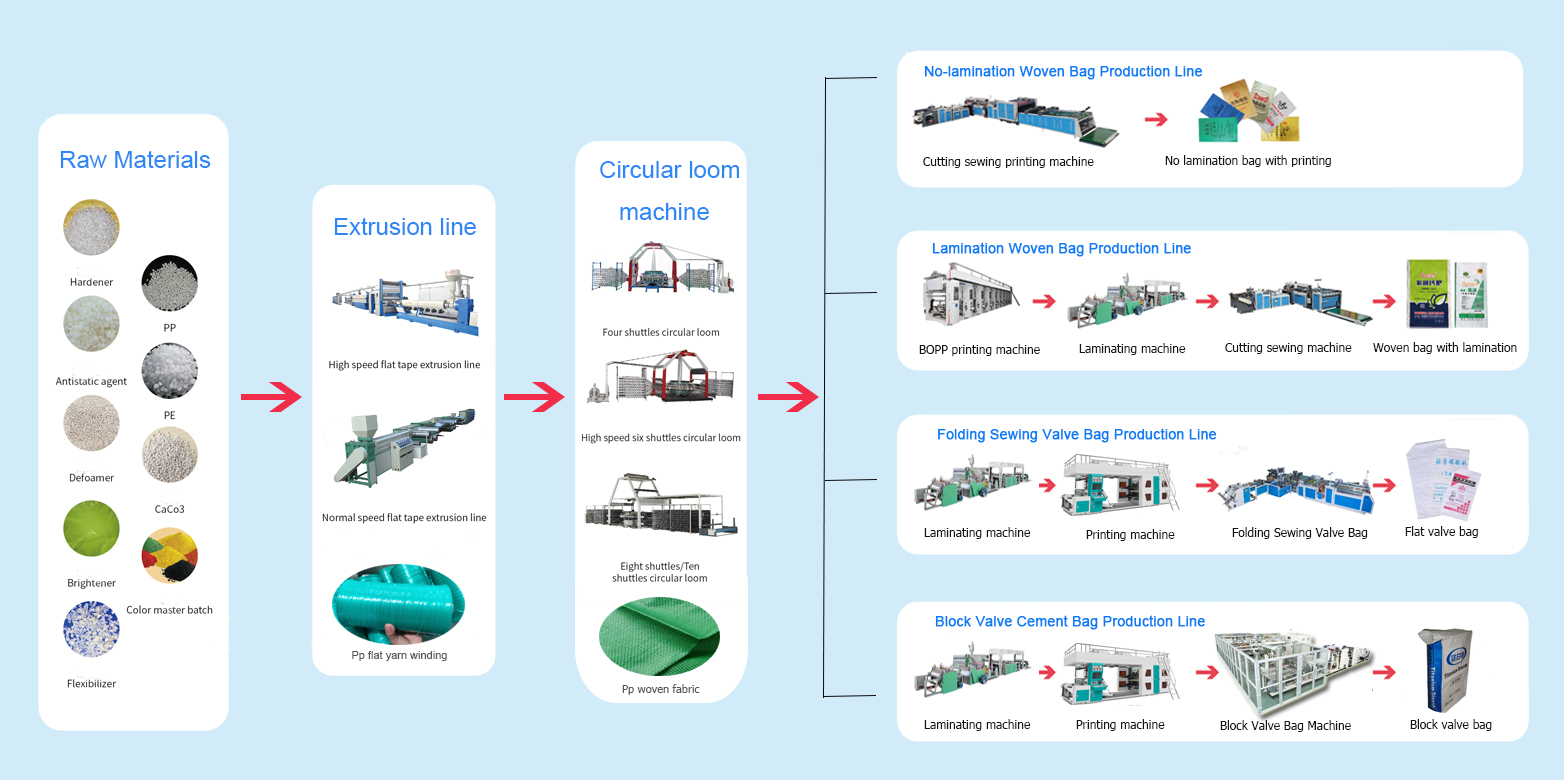

pp woven bag tape line making machine

PS: According to customer requirements can be arbitrary matching machine can be made at lower cost.

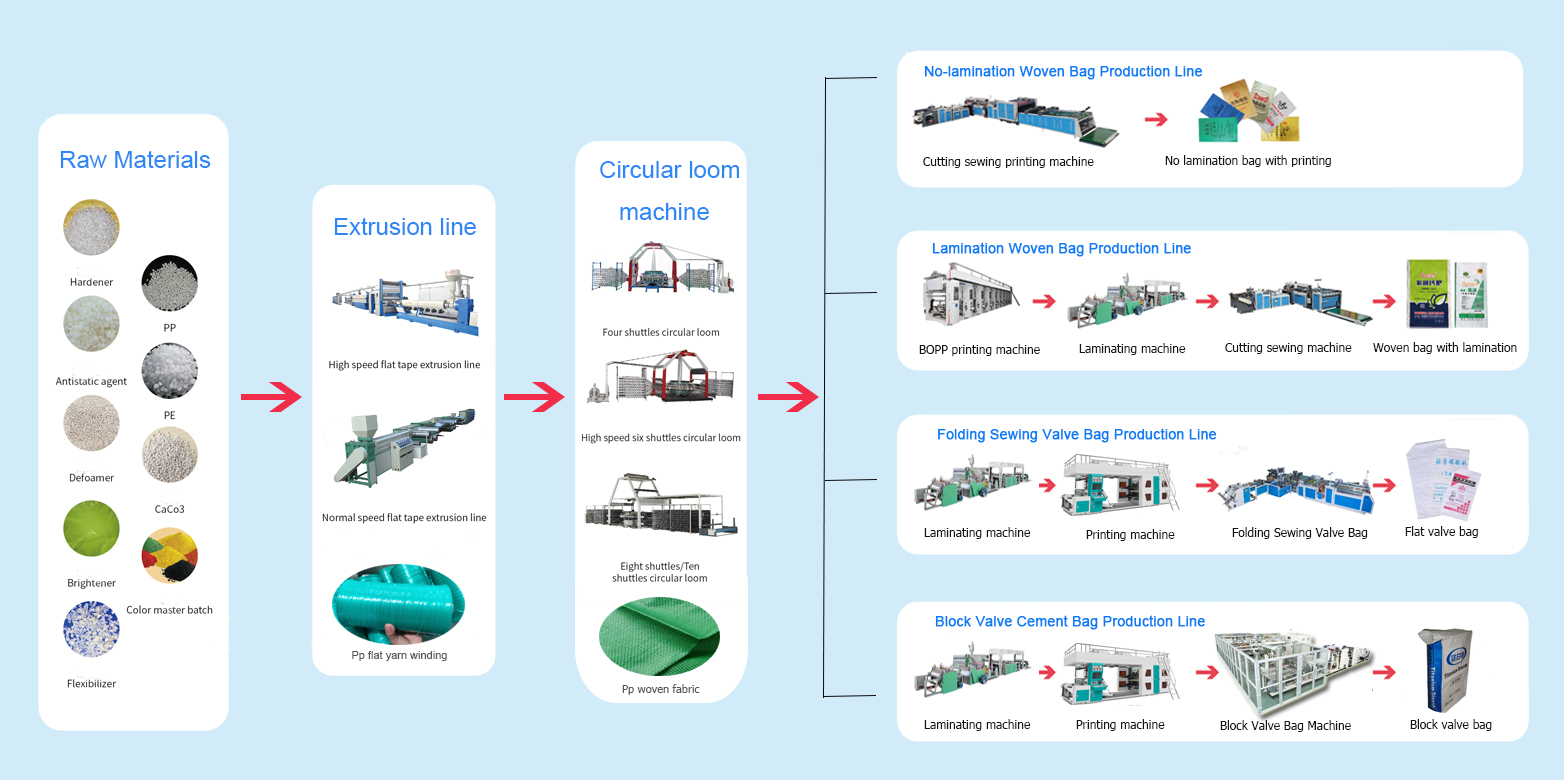

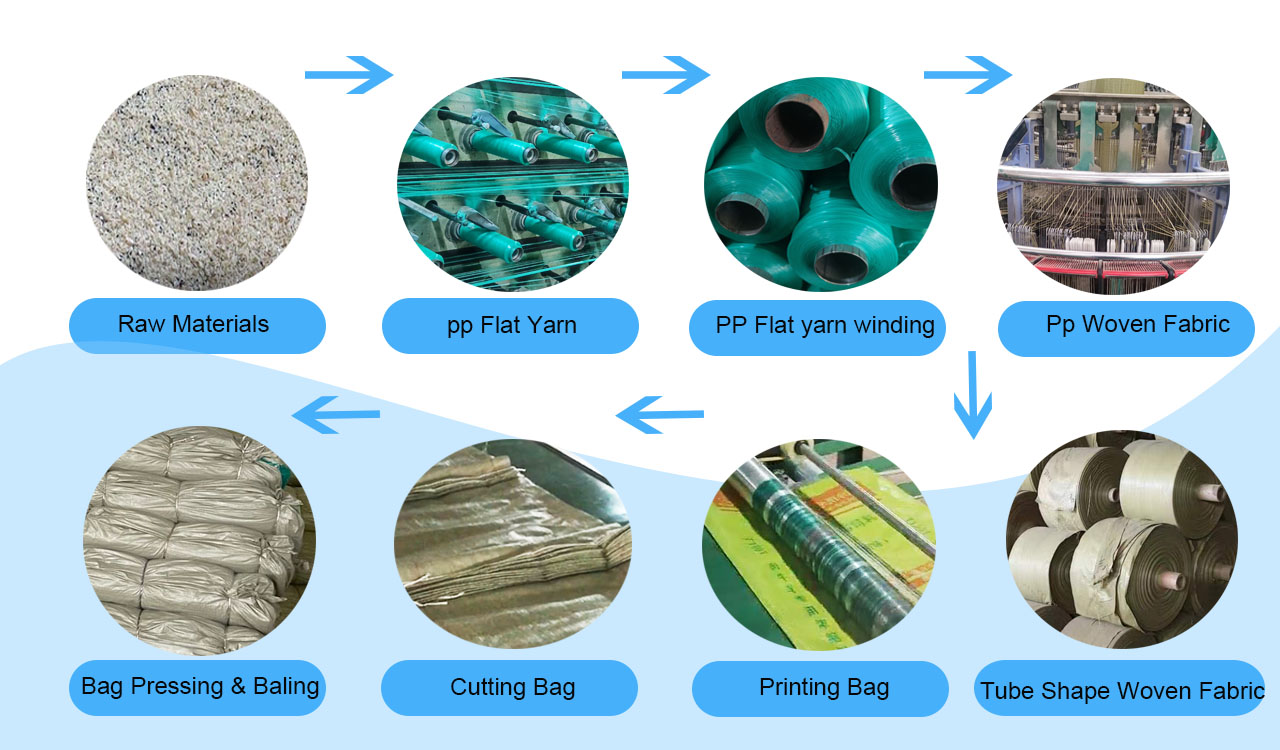

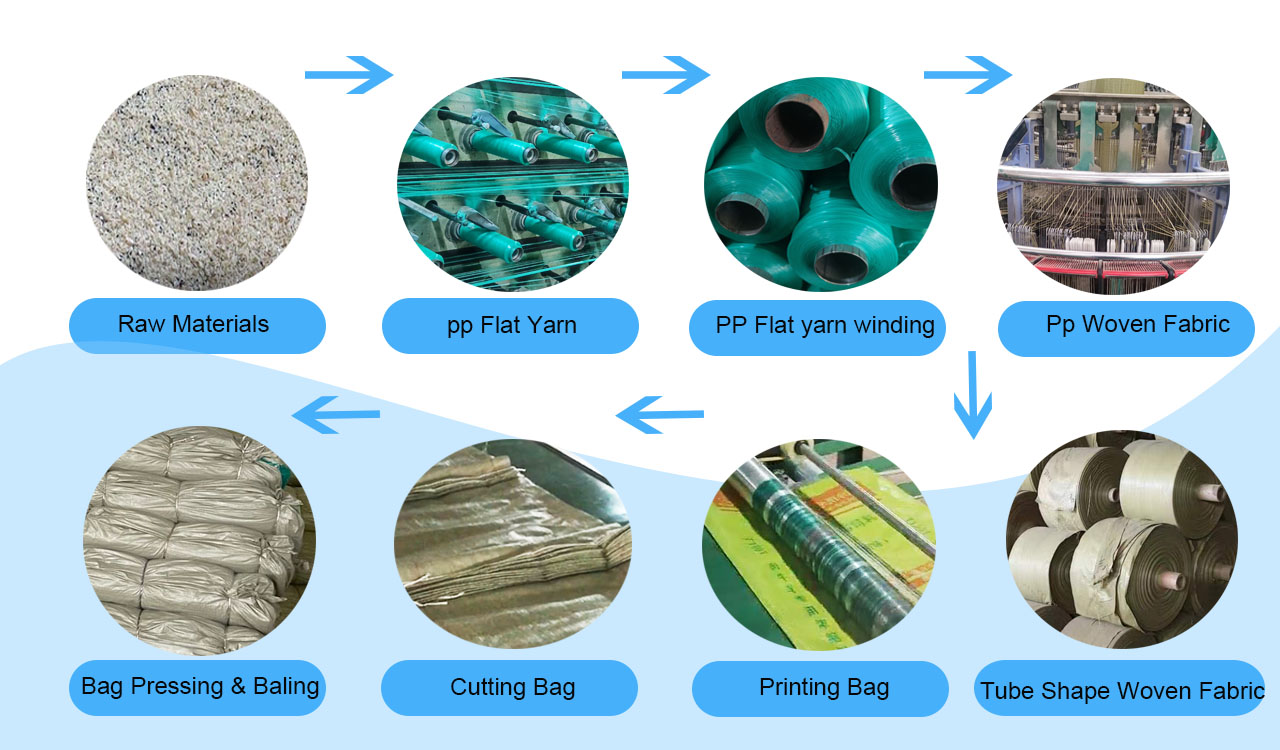

Pp Woven Sack Bag Product Process

PP Tape Extrusion Line

Diameter of screw(mm)

|

120-135mm

|

L/D ratio Of screw

|

24:1

|

Rotational Speed of Screw(r/min)

|

20-80r/min

|

Width of Die(mm)

|

1200mm

|

Tape Thickness

|

0.025-0.08mm

|

Production

|

70-120kg/h

|

Motor power of extruder (kw)

|

30KW

|

Power of driving Motor(kw)

|

4.0-7.5kw

|

Heating power of extruder (kw)

|

80KW

|

Layer Number of spindle

|

5

|

Number of Spindle

|

200

|

Width of Tape Spindle

|

200mm

|

Linear Speed of Tape Winding

|

30-160m/min

|

Power of winding machine

|

3kw

|

Dimension(L*W*H)

|

29000*2500*1500mm

|

Weight

|

15000kg

|

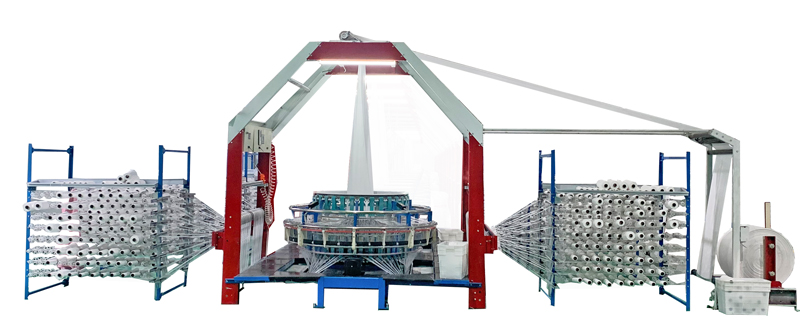

Number of shuttle

|

4 pcs

|

Width of woven cloth(mm)

|

400-750mm

|

Max Wraps

|

768pcs

|

Rotational speed of main engine(r/min)

|

140-180r/min

|

Power of machinery (kw)

|

3.5

|

Capacity(m/h)

|

100-150m/h

|

Noise DB(A)

|

<85db

|

Power of main motor

|

2.2Kw

|

Dimensions (L×W×H)

|

8400x2300x2650(mm)

|

Weight

|

1500kg

|

|

Extruder screw diameter

|

Φ90

|

Extruder length and diameter ratio

|

33:1

|

|

Die length

|

1000mm*2

|

Max fabric rolls diameter

|

1100mm

|

|

Coating Thickness

|

0.010—0.050mm

|

Mirror roller diameter

|

Φ504mm

|

|

Fabric width

|

400-800mm

|

Extruder motor power

|

15KW*1

|

|

Extruder heating power

|

30KW*1

|

Traction motor power

|

7.5KW*1

|

|

Laminating speed

|

50-130m/min

|

Installation size

|

18000mm*6000mm*2000mm

|

|

Application of Resin

|

LDPE、PP、PE、EVA、EAA、EMA Coating colophony

|

|

Basic Material

|

35-425PVC、 BOPP、 BOPET、 BOPA、 CPP、CPE、35-425g paper, nonwoven fabric, chemical fabric, woven fabric, aluminum foil, PVC, BOPP, BOPET, BOPA, CPP, CPE, linen

|

|

Starting Width

|

300-650mm

|

Speed

|

80-150m/min

|

|

Max gusseting width

|

100mm

|

Total Power

|

4 KW

|

|

Max unwinding roll diameter

|

1250mm

|

Approx. Weight

|

600kg

|

|

Max rewinding diameter

|

1250mm

|

Installing Dimensions

|

5000x1200x1700mm

|

|

Production Speed

|

25-40 pieces/min

|

Bag Cutting Length

|

400-1500mm

|

|

|

max 780mm

|

Bag Cutting Precision

|

±2mm

|

|

Folding width

|

20-30mm

|

Printing color

|

2 color

|

|

Roller diameter

|

430mm

|

Heating Power

|

5.0 kw

|

|

Feeding motor

|

3.8 kw

|

Unwinding motor

|

0.7 kw

|

|

Installation size

|

7000mm*6000mm*1400mm

|

Weight

|

1500KG

|

●14 years focus on pouch making machine!Our experienec is your advantage!

●Direct factory!

●Pouch making machine get European engineer’s praise!

●480 set machine installed!

●Origin Idea ,design by our own engineer,accept OEM or ODM!

●Highed skilled engineer ,easy operation!

●Turn-key project, remote support on line!

●Qualified machine under global safety standards to guarantee production safety and workers security.